By proadAccountId-464721

•

November 13, 2025

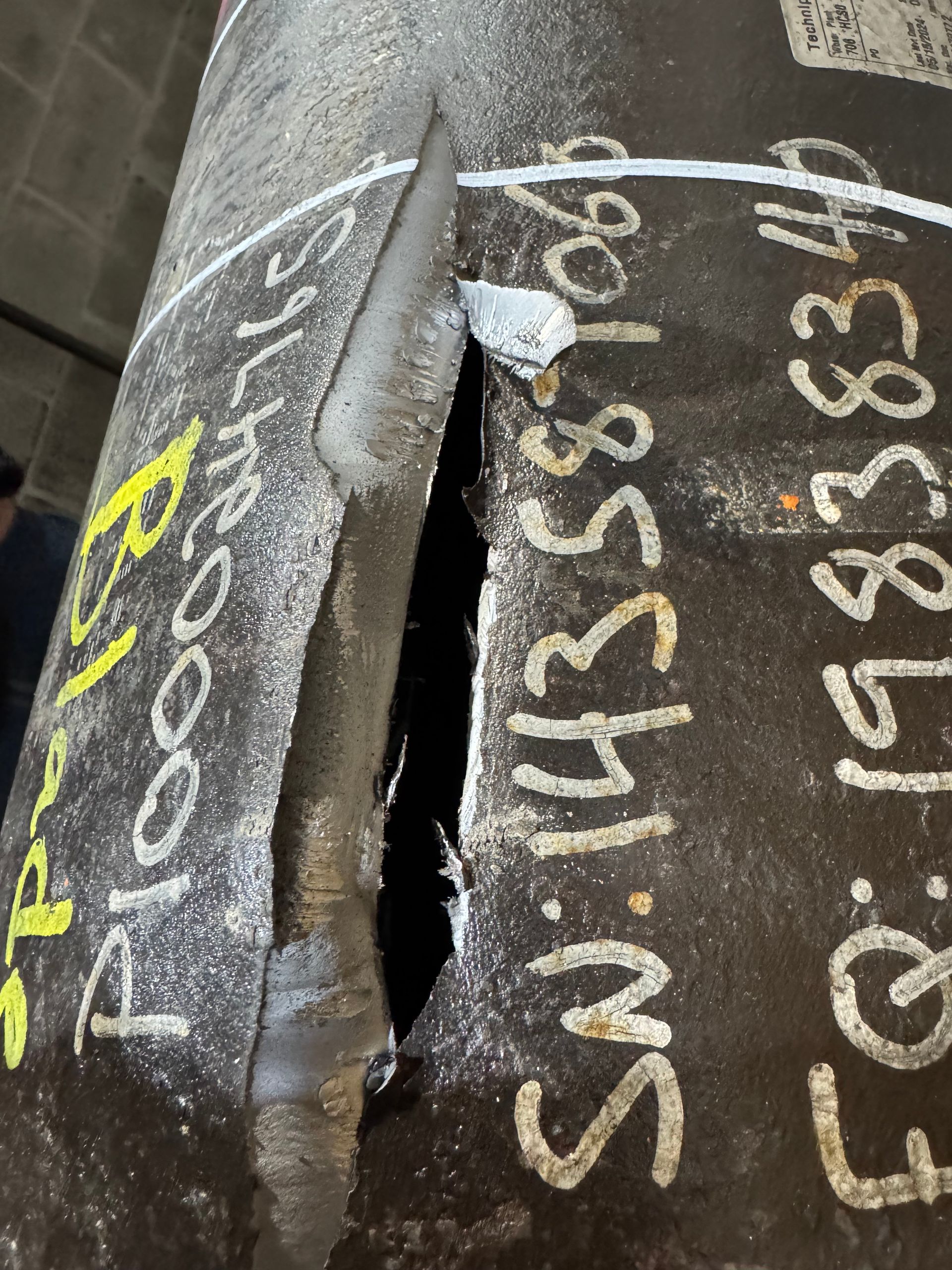

In today’s oil and gas industry, the stakes are higher than ever. Deepwater projects in regions like the Lower Tertiary Gulf of America are pushing operational limits. High-pressure, high-temperature (HPHT) environments test every piece of downhole equipment, and when traditional barrier systems fail, the results are costly: delayed completions, compromised zonal isolation, sidetracks, and increased non-productive time (NPT). Oilfield Service Professionals (OSP) set out to solve these challenges head-on. The result is a modular suite of drillable technologies; BarrierPro™, SqueezePro™, and MultiPro™ , purpose-built for extreme HPHT conditions. Backed by field-proven case studies, these systems are redefining what operators can expect from downhole barrier tools. The Problem: When Conventional Barriers Aren’t Enough Operators working in HPHT wells are all too familiar with the shortcomings of conventional drillable systems. Traditional tools struggle with: Casing ID transitions in Tieback Receptacles (TBR), often causing poor sealing or premature setting. Limited adaptability , forcing operators to carry multiple inventories of specialized tools. Reliability gaps in ultra-deepwater conditions, where small failures translate into massive costs. These limitations have a real impact. Every hour of rig time in deepwater costs tens to hundreds of thousands of dollars. Unreliable barriers mean contingency plans, wasted trips, and, in worst cases, compromised well integrity. The Solution: A Modular Suite of High-Performance Drillable Systems The OSP Drillable Technology Suite is built around three core products, each engineered to solve a specific set of downhole challenges while working seamlessly together. BarrierPro™: The Workhorse for HPHT Integrity BarrierPro™ is a cast-iron retainer/bridge plug rated to API 11D1-V3 standards, capable of handling 15,000 psi differential pressure . Unlike conventional tools that rely on composite bands or segmented slips, BarrierPro™ uses an enhanced slip-retention system that delivers reliable anchoring and sealing in extreme conditions. Key benefits: Superior reliability in casing transitions and TBR environments. Proven performance in record-setting HPHT deployments. Flexible deployment with MultiPro™ hydraulic, mechanical, or wireline systems. [Learn More] SqueezePro™: Faster, Cleaner Cement Assurance For cement remediation and zonal isolation, SqueezePro™ offers both semi and fully composite options. Its design balances high sealing integrity with easier drill-out, helping operators save time and reduce risk. Key benefits: Faster drill-out without sacrificing performance. Reliable isolation for micro-annulus remediation. Streamlined cementing assurance in challenging geometries. [Learn More] MultiPro™: Deployment Made Simple MultiPro™ is the suite’s “enabler”, a modular, field-convertible setting system compatible with multiple deployment methods. Its reduced tool OD and length improve annular clearance and drill-out efficiency, making it highly versatile in complex wellbores. Key benefits: Simplifies inventory with one system adaptable across casing sizes. Field-convertible design reduces downtime during unexpected changes. Compatible with mechanical, hydraulic, and wireline operations. Together, these technologies give operators a reliable, flexible toolkit for deepwater and HPHT challenges. Proof in the Field: Case Studies from the Gulf of America Case Study 1: Remediating a 31,000-ft Micro-Annulus with SqueezePro™ A Gulf of America operator faced severe micro-annulus issues at more than 31,000 ft in a 15,000 psi-rated well. Traditional solutions failed to achieve isolation across complex TBR transitions. Challenge: Deploy a 9-7/8” mechanical barrier in extreme depth and pressure conditions. Solution: OSP deployed SqueezePro™ with a custom centralizer, ensuring smooth placement and reduced friction. Result: The barrier passed API 11D1-V3 pressure validation at 15,000 psi. NPT was significantly reduced, and cement remediation was completed in a single trip. This application demonstrated not only technical success but also operational efficiency - critical in ultra-deepwater projects where rig time equals millions of dollars. Case Study 2: Record-Setting 34,000-ft Barrier Installation with BarrierPro™ In another Gulf of America project, an operator attempted a 34,000-ft barrier installation. Competing systems repeatedly failed due to more than 850 premium casing connections , a notoriously challenging environment for conventional barriers. Challenge: Deliver a barrier capable of setting reliably at record depth with zero tolerance for failure. Solution: OSP deployed BarrierPro™ Hydra-Set™ combined with the CleanPro™ scraper , allowing single-trip scraping and barrier deployment. Result: The first-ever successful barrier installation at 34,000 ft. No seal or setting failures occurred, and the system passed pressure tests exceeding 10,000 psi. The successful operation set a new benchmark for ultra-deepwater completions, giving operators confidence in pushing the limits of HPHT drilling. The Value Proposition for Operators The value of OSP’s technology goes beyond the technical specs. Here’s what it means in practice: Reduced Non-Productive Time (NPT): Single-trip deployment and faster drill-out translating into measurable cost savings. Inventory Simplification: A modular, field-convertible system reduces the need for multiple SKUs and contingency tools. Operational Efficiency: Compatible with multiple casing sizes and deployment methods, enabling quicker decision-making and adaptability. Proven Reliability: Field-proven in the harshest HPHT wells, minimizing the risk of costly sidetracks or failed isolation. Rapid Response: OSP’s modular design allows rig-side adaptability, reducing downtime in case of unexpected failures. For operators, these benefits improve well economics and reduce risk exposure. In today’s market, where margins are tight and project complexity is rising, that’s a powerful advantage. Looking Ahead: Expanding the Boundaries of HPHT Technology The OSP Drillable Technology Suite represents a step-change in HPHT wellbore integrity. But the journey doesn’t stop here. Future development will focus on: Optimizing centralizer systems for even more complex geometries. Expanding long-term performance testing under sustained HPHT conditions. Extending field trials into other deepwater basins worldwide. By driving continuous innovation, OSP empowers operators to transform the toughest drilling challenges into opportunities executed with confidence, safety, and efficiency. Conclusion Deepwater HPHT environments demand technologies that don’t just “get the job done,” but excel under the harshest conditions. The BarrierPro™, SqueezePro™, and MultiPro™ suite from OSP delivers just that: a reliable, modular, and field-proven solution to the challenges of zonal isolation and wellbore integrity. From a 31,000-ft micro-annulus remediation to a record-breaking 34,000-ft barrier installation, these systems have already proven where others failed. For operators, the value is clear; lower risk, higher efficiency, and confidence in tackling the industry’s toughest wells. As projects continue to push deeper, hotter, and more complex, OSP’s drillable technology suite is positioned to set the new standard for wellbore barriers in HPHT drilling.